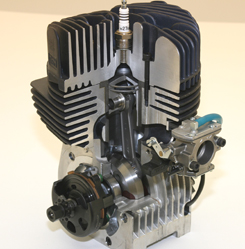

TKM engines are manufactured to a high level of accuracy and consistency. But we know how to gain the last fractions of power to give you the ultimate performance and reliability from the BT82 engine.

Our  Factory Fiche & Servicing includes:

Factory Fiche & Servicing includes:

- Optimisation of the cylinder barrel port positions using the correct combination thicknesses of base gaskets.

- Precise machining of cylinder liner top mating face & cylinder head for maximum permitted compression and ideal squish clearance.

- Accurate cylinder re-boring & honing ensuring not only correct piston/ring clearance but also that the piston bore is true to the cylinder base.

- Meticulous crank stripping and assembly which includes total dimensional checks for con-rod (B/E ovality & straightness) , crank journals & B/E pin hole fit, ensuring true running crank and straight con-rod.

- Experienced assembly throughout achieving free running engine.

- All of our tooling and machines used to rebuild engines are of the latest high quality available.

- Ignition testing facility up to 20,000 RPM.

- Computerised engine test bed cell calibrated with integral weather station giving the most accurate readings for Torque & BHP.

- All the old worn or damaged parts are always returned to customer with each rebuild giving total confidence that new parts have been fitted.

Our service rebuilds ensure that your engine will be at maximum power output and ready to win at the highest levels of racing.

We absolutely guarantee that work carried out will be totally permissible under Formula TKM regulations. However, from time to time you are advised to check that your piston rings are not stuck, as well as to remove excess carbon build up so you do not fall fail of the regulations covering stuck rings and minimum head volume.

Our competitively priced  prepared and rebuilt engines have won many major events including British Championships, TKM Festival titles, O plate and E plate victories.

prepared and rebuilt engines have won many major events including British Championships, TKM Festival titles, O plate and E plate victories.